Norton Commando Factory OEM Engine Rebuild FAQ’s

What is a Norton Commando Factory OEM rebuild?

A Norton Commando Factory OEM Engine Rebuild means that your engine is restored to original factory specifications using OEM parts and procedures approved by Andover Norton International LTD.

At Classic Bike Experience, as the first Andover Norton Factory Authorised OEM Workshop, we follow the guidelines from Norton’s factory archives and utilize their OEM components. This ensures your engine is rebuilt to the highest standard of reliability and performance while maintaining the authenticity of your classic Norton motorcycle.

What’s included in the Basic Engine Rebuild?

Here is what we do with all rebuilt Norton Commando motors:

- Bore and hone the cylinders to provide fresh metal inside for the new pistons & rings

- The head and cylinder will be checked for flatness, and decked (as necessary) to provide level mating surfaces

- Complete valve job, including new valves & guides

- Lifters will be reground

- Use new big end shells and connecting rod bolts and nuts when rebuilding the crank

- Install new main bearings

- Use all new gaskets, including a composite head gasket

- Pressure relief valve adjusted to original specs

What other options are available?

Here are additional options for your engine rebuild:

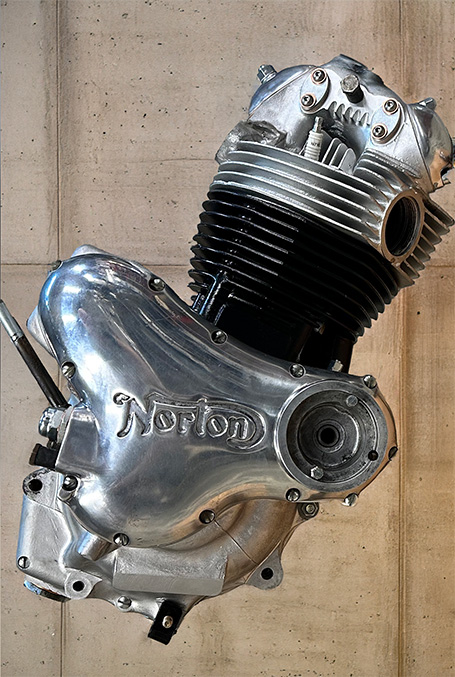

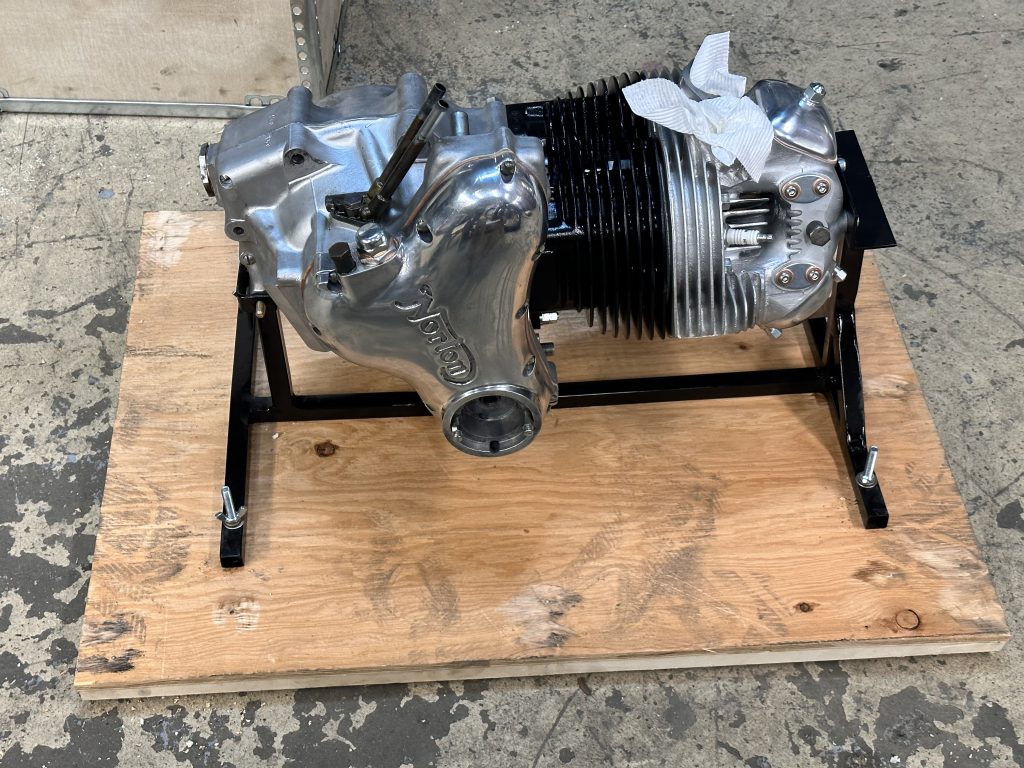

- Vapor honing of all castings

- Paint & sandblast the jugs

- Unless otherwise requested, paint will be appropriate for the year (semigloss black or silver)

- New valve springs

- New tappet adjusters

- New pushrods

- New timing chain and tensioner

- New crankshaft bolt kit

- New pressure relief valve

- New tachometer drive housing

- This version that includes rubber o-ring to reduce oil leaks

- Polishing the rocker covers and/or timing cover to a “street finish”

Do you replace all the bolts & fasteners?

We will if you ask us to, or if we are unable to use the existing ones. The calculator has a list of all available fasteners – you can pick and choose which ones you want.

Will you regrind the crank?

This machining can be done upon request for an additional fee. If you ask us to do it and it doesn’t appear necessary, we will discuss this with you prior to sending it out.

Please note: this service will be added to your invoice if we find wear, ovality, and/or scarring on the journals. If you are on a tight budget, we recommend that you include this service for your planning purposes. It will only be done if necessary, but it will avoid blowing your budget if it is needed.

What is the AMR Sump Mod?

The AMR Sump Mod (also known as the “Nortec Anti Wet Sump” mod) is our preferred method for dealing with wet sumping. The common “inline check valve” relies on a vacuum to be built up within the motor to “pull” the oil past the valve. The check valve on the Nortec is on the pressurized output side of the pump.

The modification involves installing a check ball in the timing cover, where the oil pump feed bush contacts the cover. This prevents oil from passing into the engine sump through the oil pump gears when the bike is parked. If you’re asking about this, you know that wet sumping is an issue with the Norton Commando.

In addition to the check ball installation, two O-ring seals are installed inside the oil pump. This helps to prevent oil passing between the feed and return sides.

What is the Scavenge Mod on the Combat motor?

Coming soon

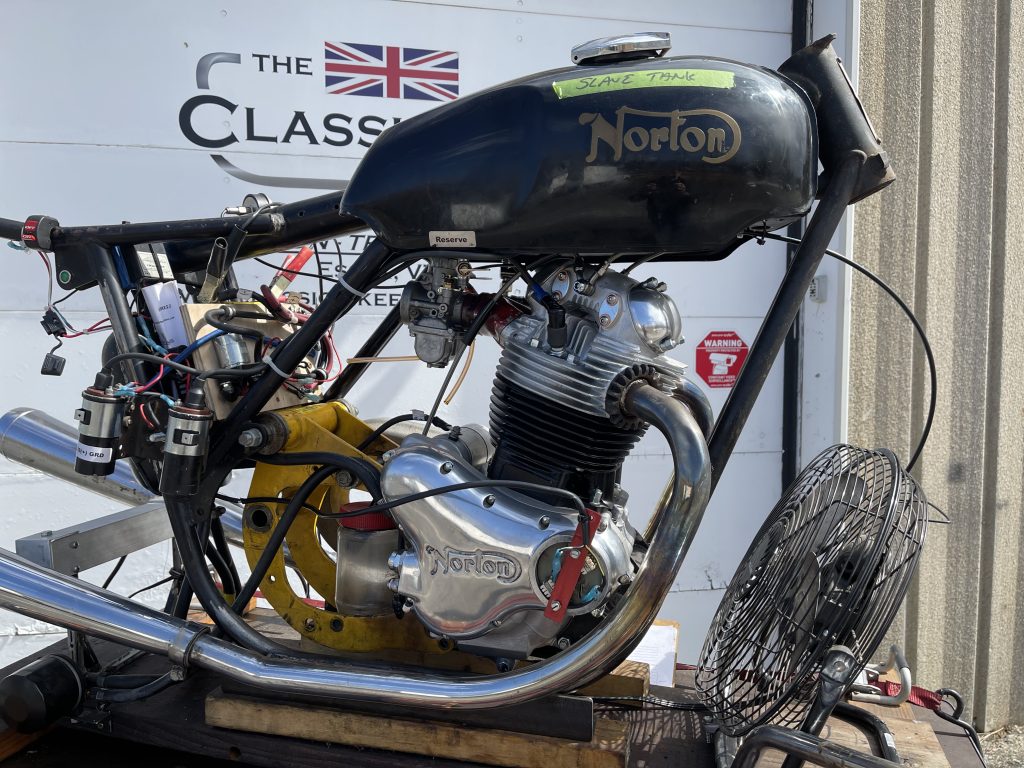

What is the test stand, and why is it necessary?

We created the test stand so that we can ensure that every motor we rebuild will run correctly. The stand has everything necessary to run the motor, such as throttle & cables, carburetor, oil tank, electronic ignition, rotor/stator, coils, and exhaust. We even added a fan to provide engine cooling.

The oil lines are clear, so we can observe the oil flow from the tank to the motor, motor to filter, and filter to tank. We test the engine as a standalone unit utilizing a Alton eStart, eliminating the need for a gearbox.

Testing is required of all motors built at CBE. If we do not have your motorcycle here at the shop, we will install your motor into our test stand prior to shipping. All testing will include:

- 10 heat cycles (operating temperature to room temperature)

- Oil pressure will be monitored throughout all cycles

- Thermal signature will be measured via IR camera

- Head and cylinder bolts will be retorqued after the fifth heat cycle, as well as after the final cycle prior to shipping.

How do you ship my rebuilt motor to me?

You can ship your motor to us complete or in pieces; it will be returned to you as a complete unit.

Shipping motors and motor parts comes with inherent risks, but at CBE, we’ve got experience on our side.

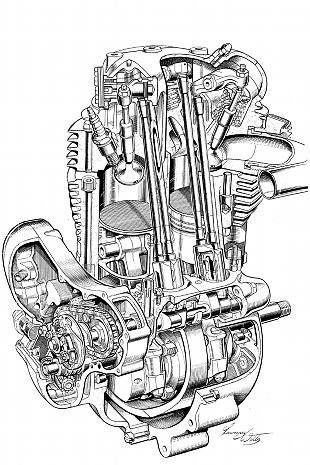

“The engine we’re looking at here is the 750cc introduced with the Commando in September 1967. Of similar design to Bert Hopwood’s Model 77 500cc unit it was based around vertically split aluminium crankcases, with a built up crank shaft consisting of a central flywheel with steel forged webs bolted to either side. Alloy con-rods were bolted to the big-end journals and the piston gudgeon pins ran directly in the little end eye. A cast iron barrel with cooling passages between the bores sat on the top of the cases, and an alloy cylinder head topped the lot off. Valves were opened by a single, four lobe camshaft, and the compression ratio was upped to 9:1 with flat topped pistons. This allowed a much shallower combustion chamber and steeper valve angles. Once in the frame the engine would be tipped forward by 15 degrees for a rakish look.” – Classic Bike Hub UK